Tube Malfunctions Visible During Operation

In general these failure modes are much less common:

If a tube will not light up, it has to be rejected. This is often caused by bad solder joints on the base of the tube and can frequently be repaired by careful application of solder to the filament connections (pins 7 and 8).

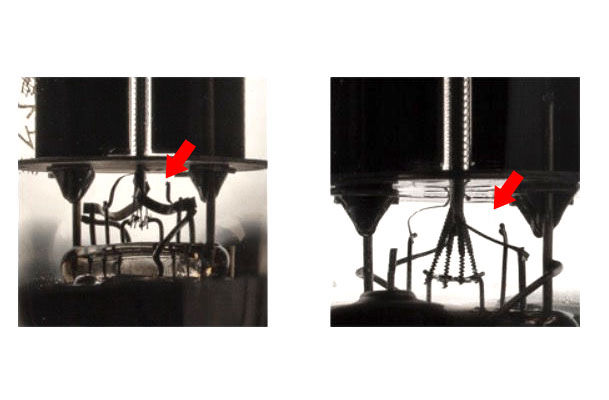

If the tube has a blue florescence just inside the glass, that is OK. On the other hand, if there is a blue or indigo florescence inside the metal structure, the tube should be rejected.

Sometimes one of the plate sections of a 6AS7G will turn 'cherry' as it is running red-hot. This may not be a tube failure, and the tube should be tried in a different power-tube socket of the amp. If it continues to turn 'cherry', it should be rejected (one the other hand, if all tubes do this in a particular socket, most likely the grid resistor associated with that tube section has been damaged- if this is the case then the tube that was in the socket when the damage occurred should be rejected). Sometimes a tube section will turn 'cherry' as the grid connection in the base of the tube has a bad solder joint (pins 1 and 4), similar to the bad filament connections mentioned above, with a similar remedy.

On very rare occasion, a tube will develop an internal short without blowing the internal fuse links. Such a tube can cause the rear panel fuse to fail. This is a case where a tube tester can be handy to look for the shorted tube.

The fuse ratings on the amps are chosen so that if the tubes are over-biased, the fuse will blow. Thus if a fuse blows and is replaced, the Bias and DC offset should be tested immediately. Start with the Bias control turned fully counterclockwise. Test the DC offset first. If there are *any* anomalies the amp should be turned off and at this point the tube tester should be used to test for shorts in the tubes.

In all cases, after a tube fault has been detected and corrected, when the amp is pressed into service, the Bias and DC offset should be tested first thing.